Did you know that over 246 million waste tires are created every year, just from cars here in the United States? While it may not have popped on your radar as a source of pollution, the tire industry and its methods of recycling rubber are rooted in outdated practices.

The Rubber Manufacturers Association says 95% of waste tires are recycled, but what does that mean? The common solution is to burn, bury, or grind them, but none of these methods are green. They all waste energy and money, plus the toxins and gases produced are damaging to the environment.

At the core of our company lies a dedication to our local ecosystems, which we call Spiffy Green. As we expand our car care solutions, we research the environmental impact and recently learned about several wide-ranging effects that tires can have on the environment throughout their lifecycle.

The Impact of Tires on the Environment

If you’ve ever had your car’s tires replaced, then you might wonder where the old ones go. More often than not, these used tires are immediately resold downmarket. While this might seem like an environmentally-friendly approach to the waste tire problem, it’s an unsafe practice that can create liability for tire manufacturers and fleet operators alike.

According to an article from Consumer Reports, “there is no way to tell if a tire has been driven while overloaded in its previous life, or driven for extended periods while underinflated, or at excessively high speeds. Each of these misuses can affect tire integrity in a way that might not be visible, leading to a possible failure down the road.” As a result, most used tires become waste, which leads to the conventional method of disposal: landfills.

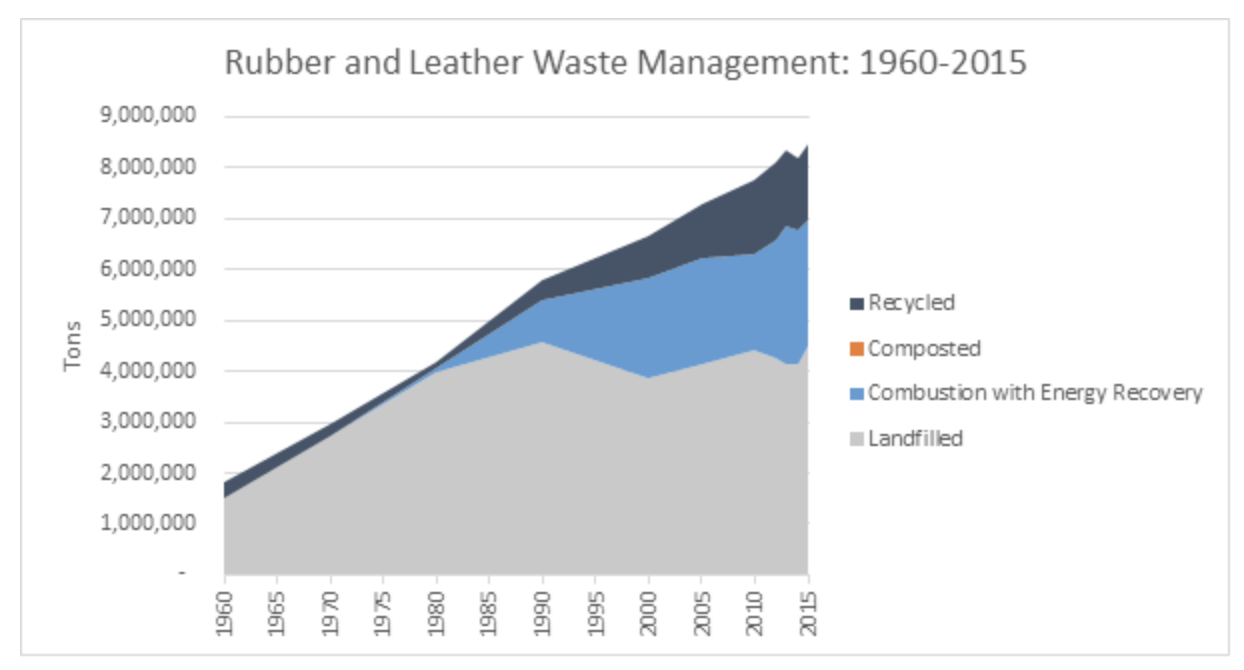

Disposing of waste tires in landfills is the most popular method by far in the United States. However, tires cause far more problems for the environment when buried in a landfill, because they take a very long time to decay and occupy vast amounts of space in our already overcrowded landfills. Data collected by Waste Business Journal last year found that “over the next five years, total landfill capacity in the U.S. is forecast to decrease by more than 15%.” Anything that can be done to keep more material out of landfills, especially the bulk of waste tires, is a positive step for the environment and the health of future generations.

Not only do tires take up space in landfills, but they also contain metals and chemicals that seep into the environment as they degrade. This is referred to as leaching, and it presents a much larger problem to local ecosystems than overcrowding. As these chemicals disintegrate in landfills, they contaminate the soil and put groundwater at risk for pollution. Any water that comes in contact with these chemicals becomes toxic, which puts humans and animals alike in danger if consumed.

Fortunately, a majority of states have made efforts to curb the number of waste tires disposed of in landfills. According to the EPA, 38 states have banned the disposal of whole tires in landfills. Of those states, 11 of them ban all tires from landfills. While many states across the country strive to address this issue, there are still eight states that have no restrictions whatsoever on placing scrap tires in landfills.

Outside of landfills, a large portion of waste tires is sent to be burnt. “Tire fire” might be a phrase you’re familiar with, but it’s far from being an eco-friendly process. Emissions from open tire fires include particulates, carbon monoxide (CO), sulfur oxides (SOx), oxides of nitrogen (NOx), and volatile organic compounds (VOCs). Despite the EPA’s choice to not consider scrap tires as hazardous waste, the agency did find that “for every million tires consumed by fire, about 55,000 gallons of runoff oil can pollute the environment unless contained and collected.”

You might be wondering, “what about playgrounds or sports fields that use shredded tires as rubber mulch?” Of the total number of tires disposed of each year, only a tiny percentage are cut up and utilized for these purposes. This can also be hazardous, as chemicals and contaminants that tires come in contact with during their lifespan aren’t removed during the shredding process.

In July 2019, the EPA began to release their findings on rubber mulch as part of the Federal Research Action Plan (FRAP) on Recycled Tire Crumb Used on Playing Fields and Playgrounds. In their key takeaways, they expressed that, “in general, the findings from the report support the premise that while chemicals are present as expected in the tire crumb rubber, human exposure appears to be limited based on what is released into air or simulated biological fluids.” It should be noted that this report is “not a risk assessment, nor can the information be used to identify a level above which health effects could occur.”

How Do We Solve the Waste Tire Problem?

All of this can sound like it adds up to an impossible situation. In spite of how wide-ranging the waste tire problem is, a company called PRTI was founded in 2013 to create and utilize technology to address it.

Their patented process, known as PRTI Thermal Demanufacturing®, is designed to be scalable across a variety of facility sizes. With such a high number of waste tires created each year, their facilities can easily be built near waste locations to minimize transportation. Unlike traditional methods that shred waste tires before processing, the PRTI solution processes tires whole. This works to reduce costs, but also produces more resources from the tires that can be sold in the future.

Their step-by-step process looks something like this:

- Trucks transport tires and related waste to a PRTI processing plant.

- Tires are loaded into the processing chamber, which uses a relatively small amount of energy to break them down into useful resources.

- Those resulting resources, which include oil, carbon, and steel, are sold or converted into power.

Breaking Down the PRTI Solution

Within their initial 3 years of operation, the PRTI plant in Franklinton, NC processed more than 50 million pounds of rubber from waste tires. The company is ready to scale and build many more plants across the US to begin to solve this waste to energy situation.

Overall, the Thermal Demanufacturing process takes 11 hours to break down 6,000 pounds of tires, per processing chamber. The only energy required is 20 minutes of propane-fueled heat, followed by 11 hours of controlled atmosphere and gravity.

This waste-to-energy solution has also enabled a partnership between PRTI and Standard American Mining, which created a cryptocurrency mine that runs on renewable energy from waste tires. If you’re interested in learning more about this, then I highly recommend listening to CEO Jason Williams’ appearance on the Off The Chain Podcast!

So what does this all mean for Spiffy? With our dedication to eco-friendly car care services, it makes a lot of sense for us to launch our new tire initiative in partnership with PRTI. We’re excited to see our Spiffy Green philosophy expand with the unique expertise of PRTI and look forward to diving into greater detail in a future blog!

Posted in News, Spiffy Green